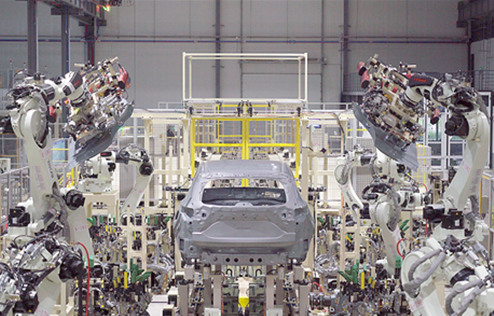

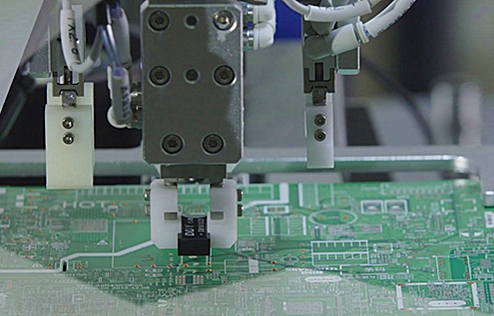

The body-in-white door cover assembly line is the production line with the highest comprehensive automation difficulty in the automotive field. Through the intelligent assembly and adjustment system, the four doors, two covers, bumpers, interior bolts, etc. can be fully automated.

Advanced digital virtual debugging offline simulation technology, machine vision technology, laser measurement technology, system ultra-high speed transmission technology, quality control system, intelligent tightening system, automatic sequencing transmission system, NC flexible positioning and other innovative technologies have been applied, and many core technologies have reached the domestic and international advanced level.

It has achieved the first fully automated, intelligent and flexible production line for automobile door covers in China and took the lead in mass production, reaching the random mixed co-line production of 8 models, and the intelligent assembly of one car, four doors and two covers in 54 seconds, which is a typical line case in the industry of intelligent manufacturing.

Automobile four-door and two-cover assembly and adjustment system