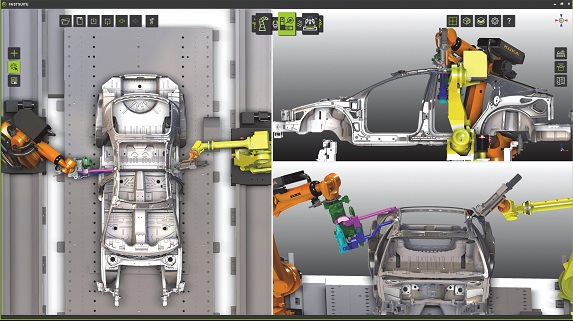

Product function:

Simulation off-line programming and virtual debugging of robot and NC equipment

Related parameters:

Rich data interfaces:

CAD:CATIA,NX,STEP,JT,IGES,Parasolid,SolidWorks.

Layout:AML, PLM, XML.

Engineering data:PMI (JT)

Abundant resource base, rapid creation of solution digital models: robots of various brands, logistics equipment, peripherals, external axes, positioner, human-machine models, etc.

Professional technology packages developed for different applications: spot welding, rolling, arc welding, laser cutting, edge sealing, gluing, spraying, riveting, etc.

Customizability, flexible function development: API, CLI extension customization, Python.

CAD:CATIA,NX,STEP,JT,IGES,Parasolid,SolidWorks.

Layout:AML, PLM, XML.

Engineering data:PMI (JT)

Abundant resource base, rapid creation of solution digital models: robots of various brands, logistics equipment, peripherals, external axes, positioner, human-machine models, etc.

Professional technology packages developed for different applications: spot welding, rolling, arc welding, laser cutting, edge sealing, gluing, spraying, riveting, etc.

Customizability, flexible function development: API, CLI extension customization, Python.